Description

The Twintrac product line was designed with performance and price in mind. The base of the Twintrac is a precision machined extrusion. The motion mechanism is comprised of a precision lead screw, with an antibacklash nut, combined with a precision round rails with two ceramic bearings on each rail. A NEMA size 23 motor (60mm square) step motor and antibacklash coupling are standard, and are included in the base price. End plate bearing housings, motor mounts are universal throughout the product line.

Options have been designed with economy in mind as well. Adjustable, optical, end of travel limits are mounted on the inside of the stage, with a flag mounted on the moving carriage. The Twintrac is designed for an optional ball screw for those customers that prefer a ball screw to a lead screw.

For multiaxis application, USAutomation offers standard XY mounting as standard options. Cable carriers, connectors and other modification are available upon request. If a special configuration is needed, as pictured above, we encourage such opportunities.

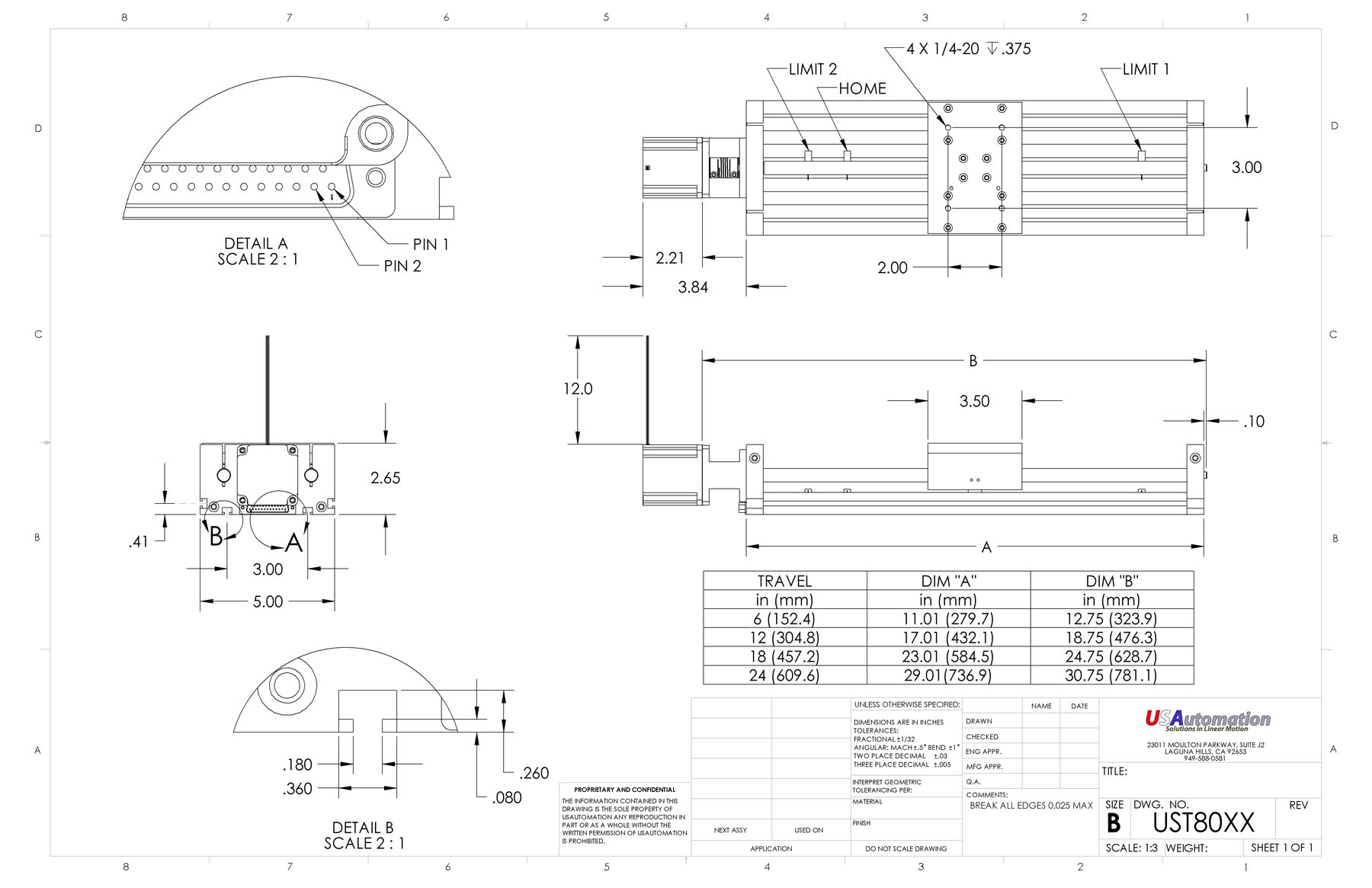

Product Drawings

Specifications

Model

Number |

Dynamic

Axial Load

(lbs) |

Travel

(mm) |

Lead

(in) |

Accuracy

(in/in) |

Maximum

Linear

Speed

(in/sec) |

Lead Screw

Efficiency

(%) |

Coefficent Of

Friction

(Constant) |

Drag

Torque

(oz-in) |

Backlash

(in) |

Motor

Torque

(oz-in) |

Weight

(oz) |

| UST8020-06 |

200 |

6 |

0.200 |

0.0006 |

5 |

63 |

0.09 |

<.5 |

0 |

175 9.5 |

| UST8020-12 |

200 |

12 |

0.200 |

0.0006 |

5 |

63 |

0.09 |

<.5 |

0 |

175 |

11.9 |

| UST8020-18 |

200 |

18 |

0.200 |

0.0006 |

5 |

63 |

0.09 |

<.5 |

0 |

175 |

14.3 |

| UST8020-24 |

200 |

24 |

0.200 |

0.0006 |

5 |

63 |

0.09 |

<.5 |

0 |

175 |

16.7 |

| UST8050-06 |

200 |

6 |

0.500 |

0.0006 |

10 |

79 |

0.09 |

<.5 |

0 |

175 |

9.5 |

| UST8050-12 |

200 |

12 |

0.500 |

0.0006 |

10 |

79 |

0.09 |

<.5 |

0 |

175 |

11.9 |

| UST8050-18 |

200 |

18 |

0.500 |

0.0006 |

10 |

79 |

0.09 |

<.5 |

0 |

175 |

14.3 |

| UST8050-24 |

200 |

24 |

0.500 |

0.0006 |

10 |

79 |

0.09 |

<.5 |

0 |

175 |

16.7 |

Mechanical